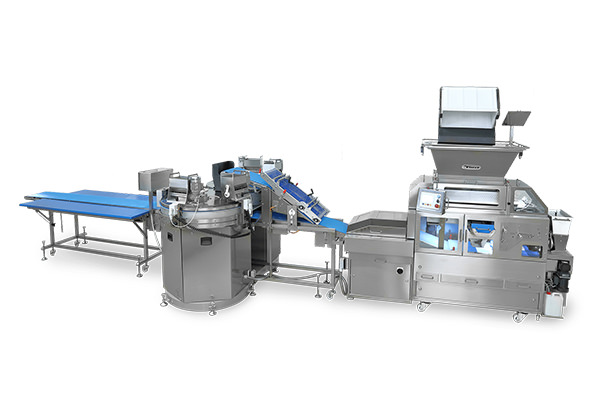

The feeding conveyor belt can be set in different positions thus ensuring the maximum flexibility in the coupling with other machines. Two adjustable centring flaps (positioned inside the hopper) centre the dough for the lamination, ensuring long-loaf breads with uniform shape and dimension. The four nylon laminating cylinders can be independently adjusted to obtain a precise lamination with all dough types. The wide gap between the two couple of laminating cylinders allows the dough to relax between the first and second lamination, obtaining in such a way a very gentle treatment of the dough. A heavy cloth, positioned just after the laminating cylinders, gives the dough a first curling to prepare it for the loafing made by the loafing table. The regulation of the loafing table is achieved by the front control-panel, easily reachable from the product exit position, which means great time saving. The moulding table is easily exchangeable and available in the flat, concave and convex versions to obtain the desired shape at all times.

- Products

-

Mixers

-

Dividers

-

Rounders

-

Moulders

-

Gravi-Line

-

Intermediate proofers

-

More bakery machines

-

Pastry machines

-

Refrigeration

-

Ovens

Edit ContentEdit Content

Alaska is the Turri Group company specialized in the production of industrial refrigeration machines.

Alaska is the Turri Group company specialized in the production of industrial refrigeration machines.

Discover the wide range of products including:- Retarder proofers

- Freezers

- Water Chillers

Edit Content

Victus is the Turri Group company specialized in the production of ovens for baking and pastry making. Discover the wide range of products including:

- Rotary ovens

- Electric deck ovens

- Tube ovens

Mixers

Dividers

Rounders

Moulders

Intermediate proofers

More bakery machines

Pastry machines

-

- Applications

- Company

- Try us!

- Contacts