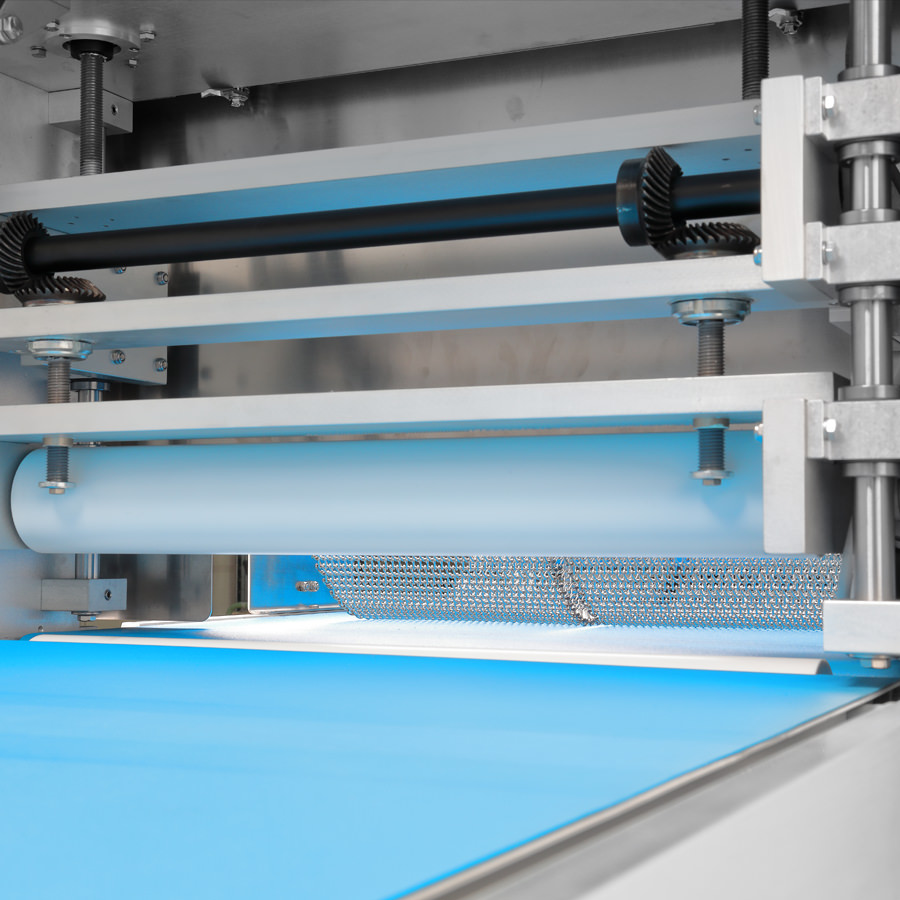

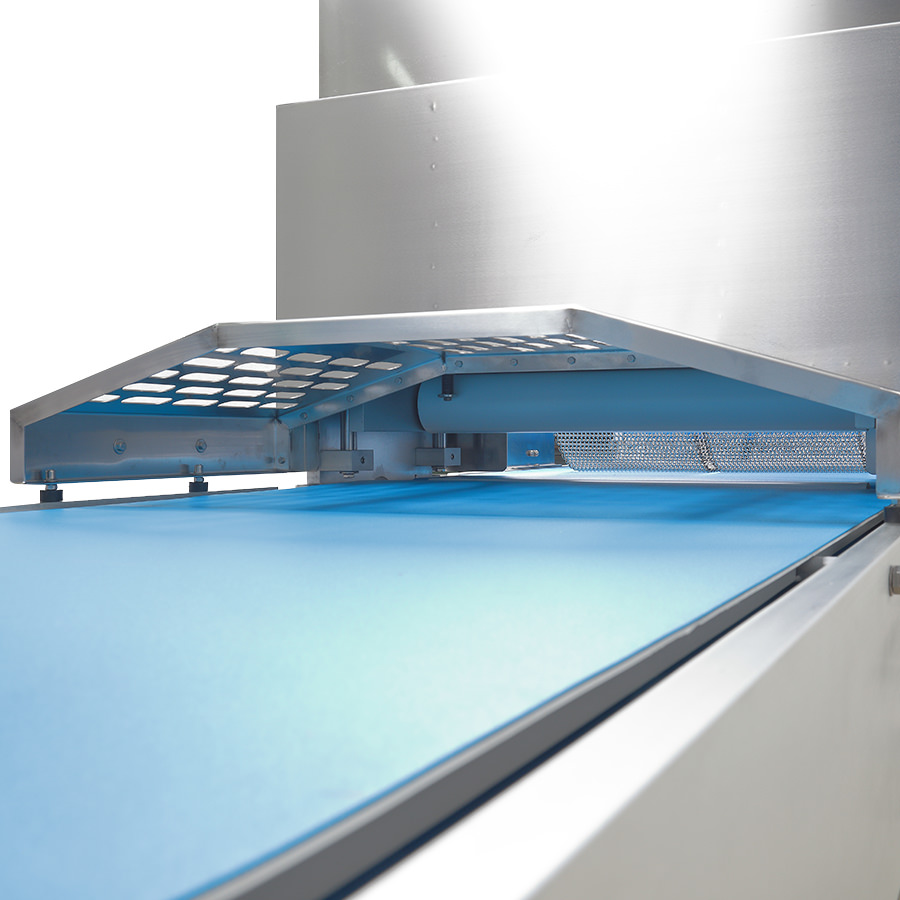

The dough is gently pressed by flattening rollers, to be then pre-rolled up by a stainless steel wire mesh. The subsequent step under the fixed pre-flattening table gives the dough the first stretch. The pieces proceed then underneath the final motorized loafing belt, which gives the final shape to the loaf thank to its opposite rotating movement. The belt speed can be adjusted in order to control for how long the piece remains under the belt, thus obtaining the desired length and shape. Equipped with lateral rails to obtain loaves with squared ends.

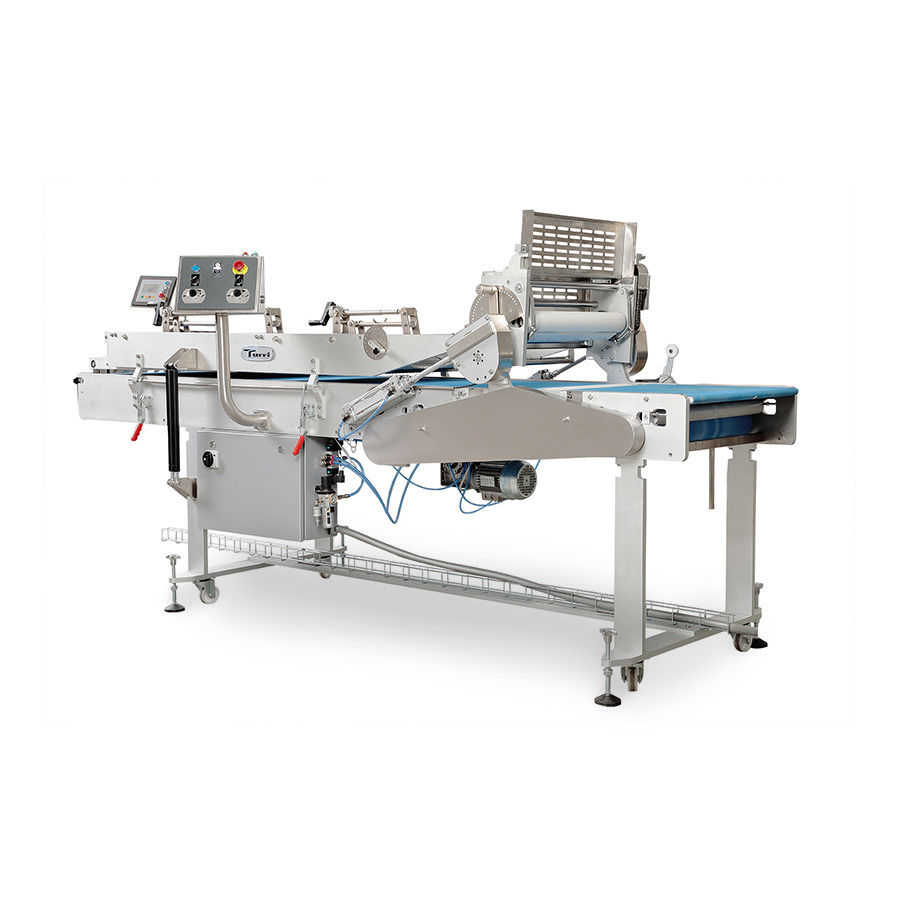

The practical lifting mechanisms (motorized for the cylinders and manual with pistons for the tables) allow to rapidly exclude Gravi-Forma for production that do not require moulding.