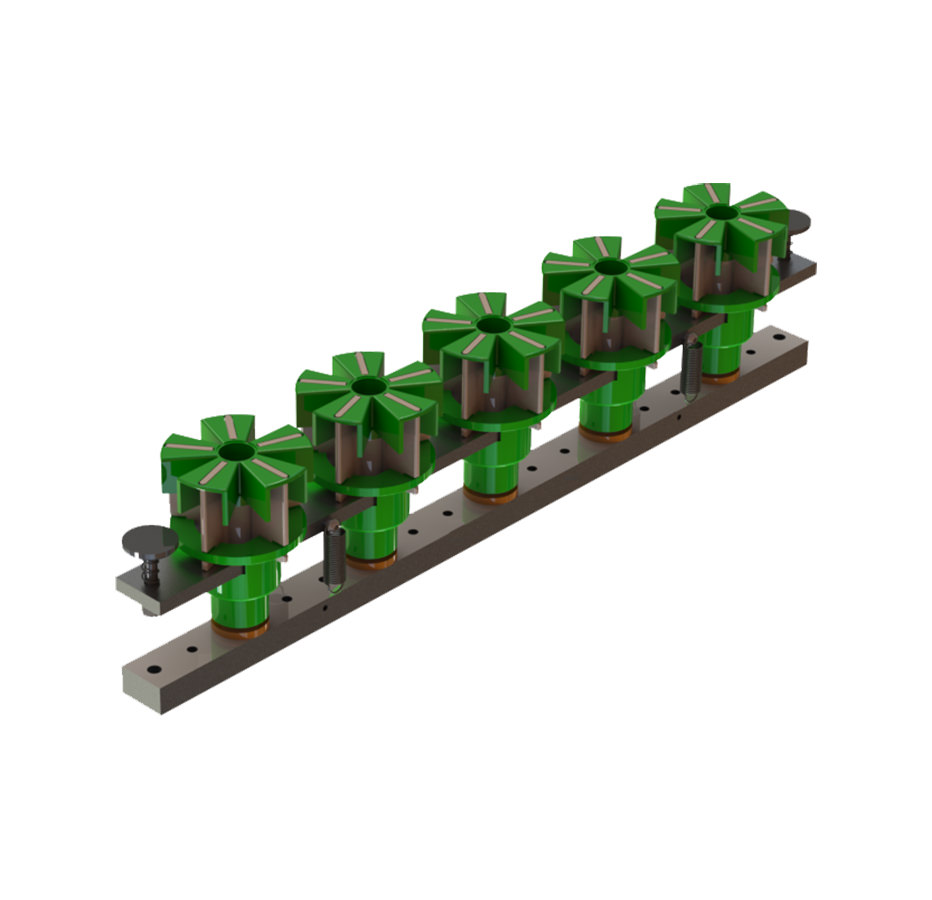

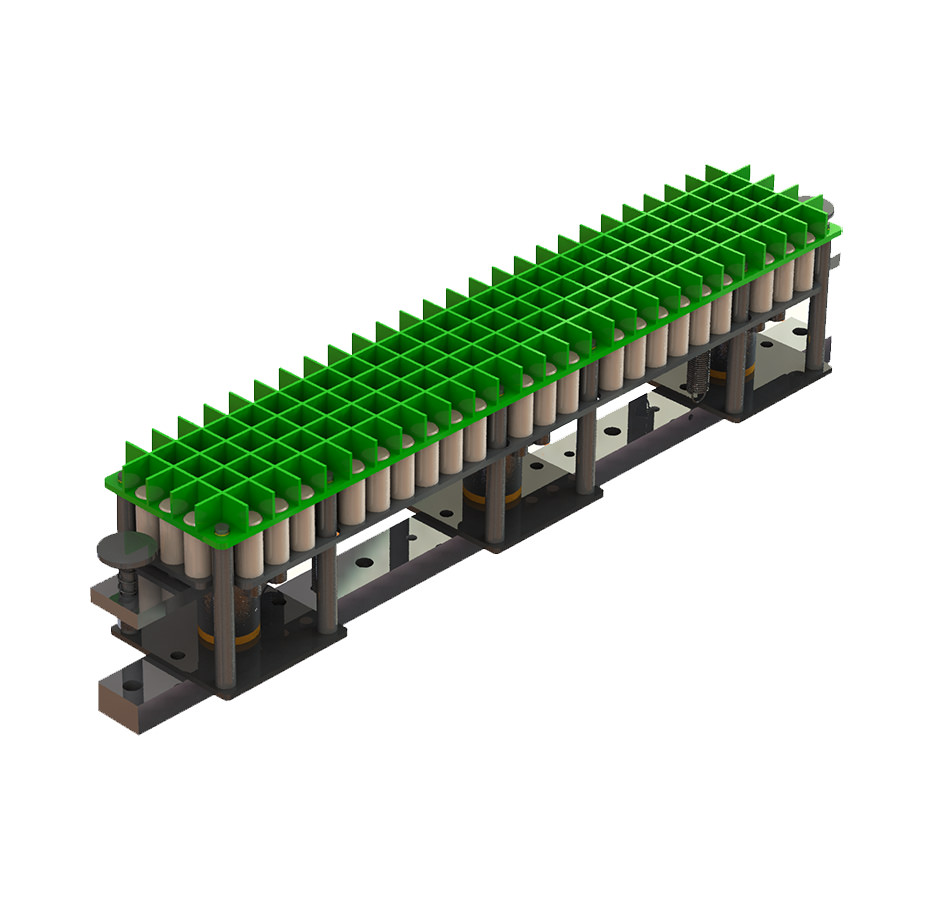

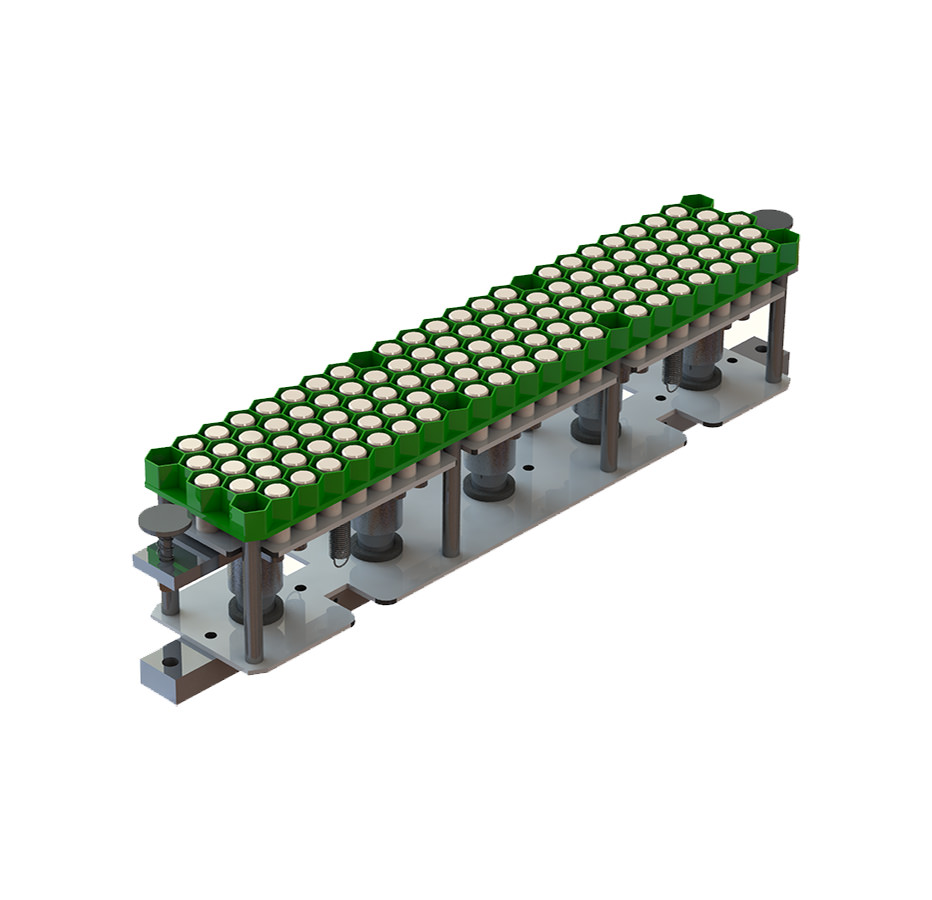

Once the pieces are placed in parallel rows on the front belt the machine can be started. The belt advances and places the pieces underneath the dies, which come down to give the dough the desired shape without compressing it. The pressing time can be adjusted with 2 timers (high position and bottom position). The dies can be changed and are supplied based on the specific customer needs. Once imprinted, the pieces are unloaded on trays placed in the below trolley, which advances automatically as the pieces fall on it until it comes out on the rear part of the machine. The stamping machine is supplied on wheels to allow ease of movement inside the bakery.

- Products

-

Mixers

-

Dividers

-

Rounders

-

Moulders

-

Gravi-Line

-

Intermediate proofers

-

More bakery machines

-

Pastry machines

-

Refrigeration

-

Ovens

Edit ContentEdit Content

Alaska is the Turri Group company specialized in the production of industrial refrigeration machines.

Alaska is the Turri Group company specialized in the production of industrial refrigeration machines.

Discover the wide range of products including:- Retarder proofers

- Freezers

- Water Chillers

Edit Content

Victus is the Turri Group company specialized in the production of ovens for baking and pastry making. Discover the wide range of products including:

- Rotary ovens

- Electric deck ovens

- Tube ovens

Mixers

Dividers

Rounders

Moulders

Intermediate proofers

More bakery machines

Pastry machines

-

- Applications

- Company

- Try us!

- Contacts