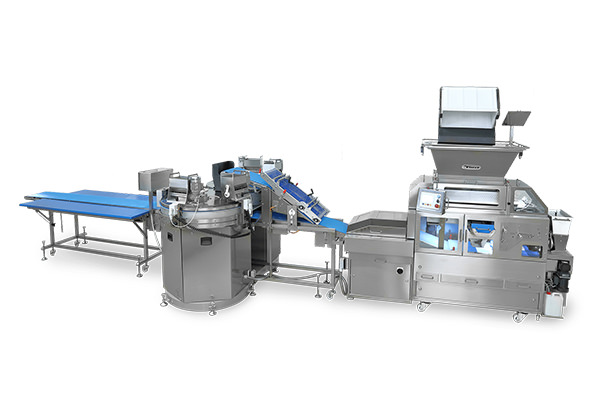

The group is made by a blade dividing machine, a first fixed moulding machine and a second swivelling moulding machine. A practical conveyor belt carries the dough to be divided and a simple dividing system delicately divides it without mistreating it. The divider allows the independent selection of weight and size, in order to cover all the different productions.

The following fixed moulder gives the pieces the first elongation. The second moulder orientation can be adjusted, to obtain the desired rolling. Keep the 2 moulders aligned to obtain long shapes such as long loaves, or place them perpendicularly to get more compact and rolled up shapes such as the “mantovana” bread.

The second moulder is also detachable, it can be used as an independent machine. Available in the G1/250 version which produces pieces from 30 to 250 grams, and in the G1/400 version for pieces from 45 to 400 grams. The high productivity of both models, up to 80 pieces per minute, allows for significant time savings in processing.